Stainless Service Center

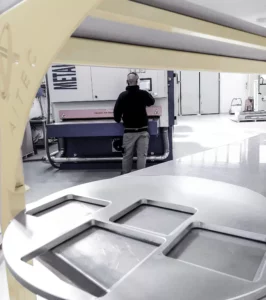

Arranged across several operational plants, it boasts a total of 8500m2 between production areas and offices. The company manages production processes with the help of a sector-specific technical ERP and a MES system that detects all production phases. Quality management is monitored by a manager (QHSE) who works following the dictates of the ISO 9001 regulation. The activities developed internally are:

The Project Manager, from the very first technical/commercial approaches, undertakes a path of loyalty and trust with the customer, working on the industrialization of projects, of individual technical tables and evaluating all construction aspects, thus defining the offer in economic and time terms. Subsequently, upon receipt of the order, he takes care of the start-up, planning, execution, control and closure of the project. Furthermore, with the help of external technicians, he also supports the customer in the design from scratch of parts or finished machines.

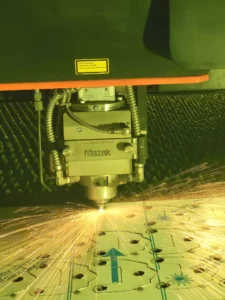

The laser cutting department equipped with modern technologies and machinery such as the Mazak fiber, working field 4000x2000mm and maximum power up to 6000W, allows considerable flexibility in the management of the various work processes and is able to manage from single sampling of a few pieces to the production of large batches, without any limits.

Furthermore, it is able to meet the different needs of customers and the sectors in which they operate as it is possible to cut thicknesses of up to 25 mm on stainless steel, ensuring a degree of precision in cutting in tenths of a millimetre and defect-free parts, ready for subsequent processing.

The variety and innovative technologies of the present bending machines allow to satisfy the multiple requests of the customers with precision and reliability, also thanks to the experience and professionalism of the operators. The department is equipped with systems for bending up to a maximum length of 4200 mm and 245 Ton. max available.

The profiles are shaped with automatic machines that allow for different cutting gradations.

With special machinery it is possible to shape and curve profiles internally and in some cases the collaboration with specialized suppliers allows to manage every different need.

CNC machine tool machining

Precision machining is performed with latest-generation CNC lathes and CNC work centers, within a new department in technology and innovation 5.0.

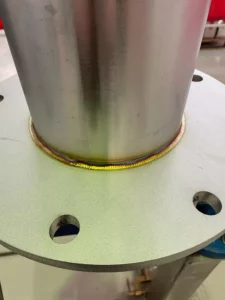

Highly qualified personnel in TIG and MIG welding, also with the aid of latest generation machines such as laser welding machines that perform certified welding with tolerance levels that comply with the parameters reported by current regulations or within the technical drawing provided.

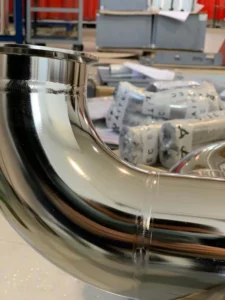

The dedicated department and the available equipment allow us to build food and pharmaceutical tanks (also PED) and any type of piping with certified welding and using control systems such as endoscopes, altimeters, roughness meters and non-destructive tests in general.

The dedicated department can guarantee a complete process from the project to the product, having acquired specialization in the assembly of any type of automatic machines and industrial plants. The complete cycle allows the internal improvement of each coupling, design choice, modification on site, before shipping the component to the final customer in any part of the world.

Additional machining operations include drilling, countersinking, tapping (with inserts and rivets), extrusion, deburring and CNC edging.

CNC controlled mechanical satin finishing using latest-generation machinery, polishing, electro-polishing, shot peening and surface pickling are manual and automatic processes performed mainly on products made of stainless steel.

The construction of pneumatic and electrical systems on board the machine is divided into different phases, all aimed at guaranteeing reliable and long-lasting solutions. The project is conventionally provided by the customer, alternatively we use external designers. The process begins with a careful evaluation of the technical and operational specifications of the project, followed by the assembly of all the pneumatic and electrical components on site, with the help of the mechanical workshop for the construction of supports or other components not foreseen by the project.

Able to produce in the industrial sector and in particular for the food beverage, pharmaceutical and Oil gas sector plants, different types of machines, complete systems and even single products.

Thanks to a competent and qualified staff combined with latest generation equipment, it is able to provide assistance to the end customer, always respecting the quality and deadlines set.

Aitec strongly believes in the real and potential capabilities of each individual employee, being the great corporate value, constantly trying to increase their skills by investing in professional and personal training.

Precisely for this reason, it is always looking for young and determined staff, so as to bring continuity and innovation to the company.

It pays particular attention to well-being, environments, motivation and professional serenity, with clear job descriptions and consolidated procedures between the various production phases and the related resources involved.

By allowing itself to be influenced by the most mature and expert players in the sector, people with experience and transversal skills, Aitec manages not to lose its know-how and to bring out the best of the construction symphonies.

The combination of these aspects allows us to always keep up with market changes, variables, flexibility, feeding the “culture” of the person and the company, thus ensuring relevance, competitiveness and the ability to meet customer expectations.

100% Traceable

Some examples realized

Examples of finished machines and plants

Frames and bases of industrial machines

Washing and containment tanks

Process plants

Transport lines

Filling and washing lines

Pasteurization tunnel

Vacuum chambers

Palletizing islands

Coclee

Helical coolers

Elevators and Descenders

Biogas plants

Slicers, kneaders, sheeters

Industrial mixers

Machines or components for industrial plants